What is a Wire Harness? | Wire Harness Assemblies 101

Table of Contents:

What is a Wire Harness

Wire Harness Assembly

Wire Harness Design and Pre-Production

Wire Harness Manufacturing/Assembly Process

Why Are Wire Harnesses Assembled Manually and Post Production Wire Testing

What is a Wire Harness?

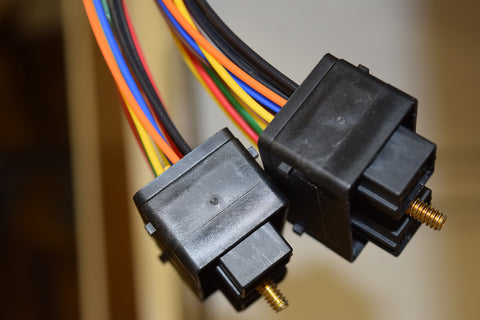

A wire harness, often referred to as a cable harness or wiring assembly, is a systematic and integrated arrangement of cables within an insulated material. The purpose of the assembly is to transmit signal or electrical power. Cables are bound together with straps, cable ties, cable lacing, sleeves, electrical tape, conduit, or a combination thereof. The wire harness simplifies the connection to larger components by integrating the wiring into a single unit for “drop-in” installation.

Wire Harnesses vs. Cable Assemblies

Wire harnesses are often confused with cable assemblies however, the two are quite different. The main difference is that a cable assembly normally has only two ends, whereas a wire harness contains multiple breakouts (ends) that run in many different directions with multiple terminations on each breakout.

Wire assemblies are most commonly used in the transportation industry, including automobiles, buses, trucks, and planes. Construction machinery, industrial equipment, electronics and white goods (household appliances) will also be constructed using wire harnesses.

Wire Harness Assembly Benefits

Decreased installation time: Many vehicles require miles of wiring in order to operate. A wire harness assembly process greatly simplifies the manufacturing of these vehicles by integrating all the wires and cables needed into a single apparatus. The installation then becomes a simple matter of “dropping in” the harness, rather than running all of the wires individually.

Security and safety: When wires and cables are bound within a single harness, the individual components are more secure against the adverse effects of vibrations, abrasions and moisture. Space is optimized and the risk of an electrical short is reduced because the wires have been constructed into a non-flexing bundle. The risk of electrical fire is also reduced when the wires are bound within a flame-retardant sleeve.

Wire Harness Design and Pre-Production

A wire harness process is designed based on the geometric and electrical requirements of the equipment it is to be installed in. Once the initial design is established, a schematic is used to create the manufacturing paperwork and the assembly board for the harness. The assembly board, also called a pin board, is a full-size diagram of the harness which shows all of the components and their locations. It also serves as the workbench for the harness.

Wire Harness Manufacturing/Assembly Process

The wires needed for the harness are first cut to the desired length and labeled appropriately. Next, the ends of the wires are stripped to expose the uninsulated conductor and fitted with any required terminals or connector housings. The wires and components are then assembled on the pin-board to the desired specification and then bound together.

Why Are Wire Harnesses Assembled Manually?

Wire harness assembly process is one of the few remaining manufacturing processes that is more efficiently done by hand, rather than automation. This is due to the variety of processes that are involved in the assembly. These manual processes include:

- Installing terminated wires in various lengths

- Routing wires and cables through sleeves and conduits

- Taping breakouts

- Conducting multiple crimps

- Binding the components with tape, clamps or cable ties

Because of the difficulty involved in automating these processes, manual production continues to be more cost-effective, especially with small batch sizes. This is also why harness production takes longer than other types of cable assemblies. Production can take anywhere from a few days to several weeks. The more complicated the design, the longer production time is required.

However, there are certain portions of pre-production that can benefit from automation. These include:

- Using an automated machine to cut and strip the ends of individual wires

- Crimping terminals on one or both sides of the wire

- Plugging wires pre-fitted with terminals into connector housings

- Soldering wire ends

- Twisting wires

Post Production Wire Testing

The final step of the assembly process is to test the harness for electrical functionality. This testing is done with the aid of a pre-programmed test board. The test board is programmed with the required electrical characteristics and the completed harness is then plugged into the board and checked for faults.

Hopefully, this blog has answered most of your questions regarding wire harness assemblies. If you are wondering if custom wire harness might be right for you. Look no further, we’ve got the answers you need.