Powder Coat vs Paint

Let’s take a look at why powder coating is often the preferred metal coating for industrial equipment and beyond.

Powder Coating vs. Paint Applications

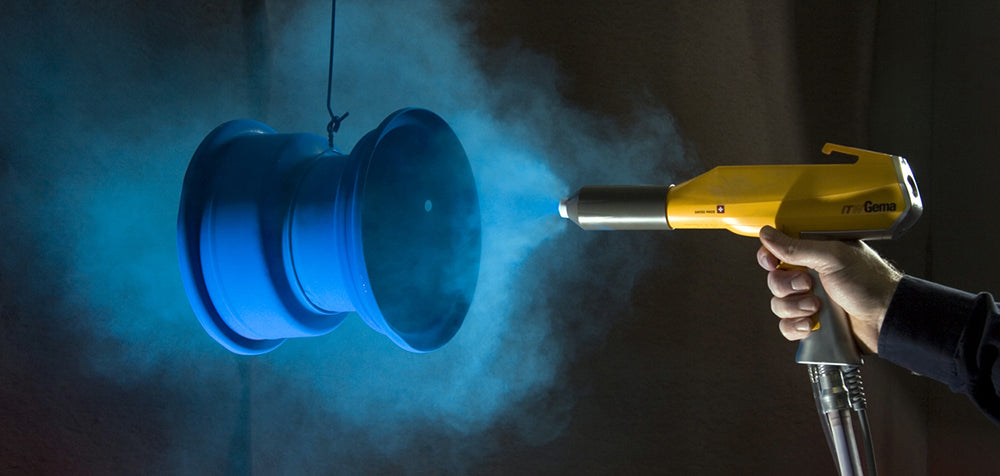

Both paint and powder coat require similar surface prep and utilize a spray “gun” to apply the specific material, but that’s where the similarities end. Traditional wet painting involves spraying paint that requires a solvent to keep it in its liquid form. Once applied, most surfaces need anywhere from a few hours to a few days to cure depending on the temperature and humidity. In contrast, powder coating uses an electrostatic gun to apply a positive charge to the powder sprayed on a negatively charged (grounded) surface. A unique benefit of the charged powder application is that the positive charge will repel excess powder, preventing it from being applied too thick. The work piece is then baked at 350 degrees (minimum) for a short period to melt, bond, and cure the coating. The coating is fully cured before it cools to room temperature. This process allows for the rapid completion of coated products.

Powder Coating vs. Painting Physical Properties

Thickness:

- Wet Paint: 0.5 – 1 mil

- Decorative Powder Coat: 2 – 6 mil

- Functional Powder Coat: 6 – 10+ mil

Powder coating is one of the most durable finishes available for metal applications. It is generally 2-10 times thicker than paint. Most modern applications receive what is considered a decorative finish, but don’t let the term decorative fool you. This is a very strong, durable coating and is often the standard used. For extra protection, a functional finish can be applied. Powder coating also allows the option of a wide variety of finish styles. You can choose from unlimited colors in gloss, metallic, matte, and more – in smooth or textured finishes. We suggest discussing specific finish recommendations with a qualified professional powder coater.

Notice the variety of color and texture options available with powder coating.

Even the thinnest decorative powder coat is physically harder than paint. While being extremely hard, powder coat can still withstand bending without cracking or flaking. It also adheres to metal material significantly better than spray paint. Powder coating creates more of a “skin” around the metal. This leads to greater chip and scratch resistance, extreme flexibility, and a longer lifespan.

Powder Coat vs. Paint Corrosion Resistance

Plan to powder coat shortly after fabrication

Powder coating offers improved corrosion resistance over regular spray paint. Salt spray testing is an accelerated corrosion test method used to evaluate the ability of a coating to provide a protective finish. Decorative powder coat finishes have shown to last over 1,000 hours and functional finishes show even more resistance to corrosion. These results are drastically greater than wet paint. Powder coating can still scratch or chip, but that if it happens the corrosion potential is isolated and will not continuously spread as with spray painted finishes. Corrosion resistance is especially important in freshly fabricated parts or machinery like shown here.

Powder Coating Environmental Impact

Another advantage of powder coating is its reduced environmental impact. The solvents in wet paint mentioned above include pollutants known as volatile organic compounds, more commonly referred to as VOCs. Powder coating involves no solvents and releases a negligible amount of VOCs into the atmosphere. Also, there is increased efficiency with powder coating compared to paint. The powder is physically attracted to the substrate through the electrical charges, thus drastically minimizing overspray. And unlike paint, the overspray can actually be collected and reused. This helps reduce both environmental impact and costs.

Another advantage of powder coating is its reduced environmental impact. The solvents in wet paint mentioned above include pollutants known as volatile organic compounds, more commonly referred to as VOCs. Powder coating involves no solvents and releases a negligible amount of VOCs into the atmosphere. Also, there is increased efficiency with powder coating compared to paint. The powder is physically attracted to the substrate through the electrical charges, thus drastically minimizing overspray. And unlike paint, the overspray can actually be collected and reused. This helps reduce both environmental impact and costs.

Disadvantages of Powder Coating

While we shared many reasons why powder coating is often the preferred finish, there are times when we choose wet paint – and you might too. The two biggest reasons are costs and necessity. With the greater durability of power coating comes a higher cost. While we won’t sacrifice quality, sometimes that cost can be spared because paint is more than sufficient for the application. Many of our custom automation projects aren’t intended for the harsh environments that call for increased protection. We recommend powder coating in most situations, but know that each application is different. Have a custom project in mind? Send us an RFQ today.

Your Powder Coating Experts

Don’t hesitate to contact us if you aren’t sure which finish is best for your application or have any further questions on our choice of powder coat or paint used in custom manufacturing. We are always willing to help.

BONUS: Here is a quick video of a VERY small scale version of the powder coating process to see the process and outcome mentioned above.