PLCs Explained: Programmable Logic Controller Basics

What is a PLC?

A PLC, or programmable language controller, is a compact industrial computer designed to control system processes from one location. You may have heard about PLCs but haven’t fully grasped the concept. PLCs are like the brains of industrial automation equipment. Instead of having several machines or workers managing different systems and equipment, PLC controllers can complete various tasks at once with a built-in I/O module (inputs and outputs). Programmable logic controllers are everywhere and heavily used across many industries. This post will dive into the main components of a PLC, programming languages, types of PLCs, and PLC systems in the future.

Traffic light signals are a great example of a PLC application. Instead of having someone reading data and pushing buttons, there is now a PLC system in place to control and monitor this function within one housing unit. If programmable logic controllers are relatively a new concept for you, then it might be hard to imagine the many types of possible PLC applications around you. Other recognizable PLC applications include automatic car washes, elevators, automatic doors, and amusement rides.

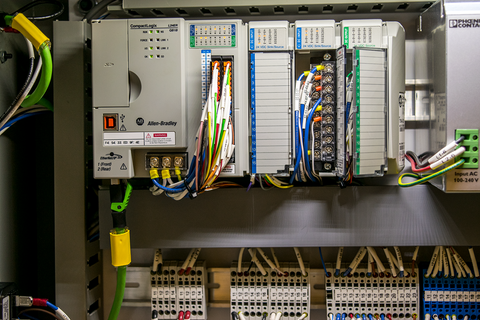

PLC in automation equipment

History of PLCs

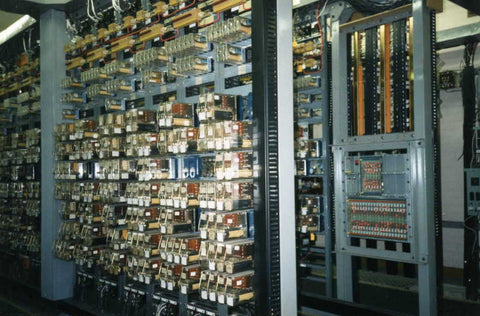

To understand the purpose of a PLC, we’ll need to go back in time to the 1960s. Picture transistor radios, Barbie dolls, G.I. Joe action figures, and Chevrolet Impalas. Machine processes during this era were controlled through the use of electromechanical relays. We’re not talking about a few relays either, these systems took up entire walls. However, the size of the relay-powered machines was not the only disadvantage.

Downsides of relay-powered machines:

- Hard-wiring had to be done in a very specific order.

- Time-consuming troubleshooting.

- Constant troubleshooting due to worn relay contacts.

- Strict maintenance schedule.

- Large and cumbersome.

- Changes involved entire system rewiring.

It wasn’t long before engineers began brainstorming solutions to these pain points. With the introduction of computer control in the industrial sector, the first version of the PLC was developed. The invention of the programmable logic controller is attributed to Richard Morley and his company, Bedford and Associates.

Example of a relay room before PLCs

PLC Advantages

Richard and his team focused on ensuring maintenance electricians and plant engineers could easily understand and use this new programmable controller. Naturally, the process took much trial and error to get to a controller that solved all the previous pain points while still being user-friendly. Eventually, they were able to achieve this with the MODICON 184.

Nowadays, PLCs offer several advantages over the hardwired relays including reliability, flexibility, cost effectiveness, speed, better communication, and advanced data processing functions. However, the most unique advantage to PLC systems is the ability to reprogram them. Therefore, they’re highly adaptable to changes in processes or monitoring application requirements.

In addition, programmable logic controllers feature several diagnostic tools that facilitate easy troubleshooting such as:

- Report generation

- Fault Logs

- Step-by-step program simulation

- Manually run inputs/outputs

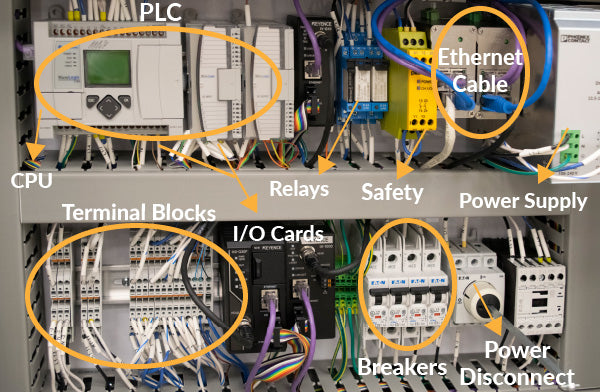

PLC Components

When thinking of PLCs, you might be thinking of a large device with many buttons and plugins, but in fact, PLC controllers are small compact devices integrated with other hardware and software components. To understand a PLC system, it is best to breakdown the system into two primary parts: the central processing unit (CPU) and the input/output (I/O) interface system.

PLC CPU

The central processing unit contains memory and a communication system needed to instruct the PLC on how to perform. Hence, the reason why CPUs are the “brain” of programmable logic controllers. This is also where data processing and diagnostics take place. The memory unit provides a permanent storage location to store programs without losing information when turning off machines. You can choose memory sizes based on the tasks assigned by the PLC. The communication system allows the CPU to communicate with other devices such as I/O devices, programming devices, and other PLC systems.

You will also need a communication port, a chassis or rack, and a programming device such as an external computer. Depending on the type of PLC, many of these components are combined into a single device. For example, a compact module may have a CPU with a set number of I/O and a specific communication port. We will discuss each component and the options available for each.

PLC I/O

Input/output (I/O) modules relay the necessary information to the CPU and communicate the required task in a continuous loop. Input and output devices can either be digital or analog form: digital devices are finite values represented in values of 1 or 0, analog devices are infinite values, and measure ranges of currents or voltages. Inputs or providers are switches, sensors, and smart devices in analog or digital forms. Outputs can be motor starters, lights, valves, and smart devices. Many types of I/O modules are available to get the right configuration to run your machine.

Additional Notes: The power supply either comes integrated with the base module or sold as a separate component. Two of the most common voltage ranges available for PLCs include 12-24VDC and 110/220 VAC. Make sure the voltage range you choose is enough to power the CPU and I/O modules.

PLC control panel

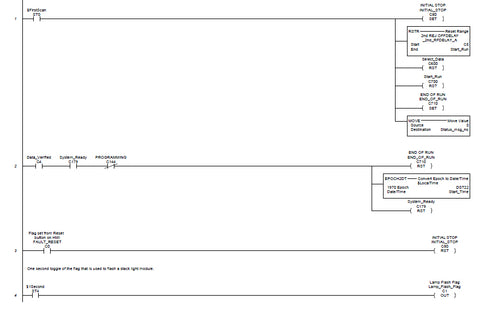

PLC Programming

PLCs require programming before they can function and perform their given tasks. These programs are usually written in a programming device or software. The program is then downloaded into the memory or RAM of the programmable logic controller. Based on the written program the CPU can read the information provided by the inputs and instruct the PLC to execute the desired outputs. There are many programming languages available to configure your PLC system.

According to IEC 61131, there are 5 standard programming languages available:

- Ladder Diagram or Ladder Logic (LD)

- Function Block Diagram (FBD)

- Structured Text (ST)

- Sequential Function Chart (SFC)

- Instruction List (IL)

Ladder Logic

Ladder logic is the most popular programming language for PLCs. It is a highly used and recognized programming language in many manufacturing industries. Because of its visual layout it is easy to read and program. Ladder logic is a program written in symbols that translate opening and closing relays, timers, shift registers, counters, and mathematical operations. The written symbols deliver the user’s program to the PLC system.

Ladder logic example

PLC Operation

If you are trying to understand a PLC system better, it will be beneficial to learn how a PLC controller operates once the program is written and the appropriate I/O modules are selected. The programmable logic controller will process the given information (inputs), execute the instruction from the program, and deliver the results (outputs) based on the provided information and written logic. PLCs operate in a repeating loop once the user determines the inputs and outputs.

The four basics steps in PLC operation are:

- Input Scan - Detects the state of input devices connected to the PLC

- Program Scan - Executes program created by user

- Output Scan - Operate all output devices connected to the PLC

- Housekeeping - Communicates with other devices and runs diagnostics

Types of PLCs

Unitary PLC

Unitary PLCs, also known as compact or integrated PLCs, are the simplest type of PLC controller and are suitable for simple processes. A unitary PLC will have a set number of I/O points and an integrated CPU with connection ports. Usually, you can directly connect these controllers to the device or application in question.

Unitary PLCs, also known as compact or integrated PLCs, are the simplest type of PLC controller and are suitable for simple processes. A unitary PLC will have a set number of I/O points and an integrated CPU with connection ports. Usually, you can directly connect these controllers to the device or application in question.

Modular PLC

Modular PLCs, also known as rack-mounted, give you more flexibility. You’ll still need a base module which will include your CPU, inputs, and power supply. However, you can customize the PLC by adding additional I/O modules. You can basically go wild here adding as many modules as the PLC allows. You could even insert an analog to digital signal converter.

Modular PLCs, also known as rack-mounted, give you more flexibility. You’ll still need a base module which will include your CPU, inputs, and power supply. However, you can customize the PLC by adding additional I/O modules. You can basically go wild here adding as many modules as the PLC allows. You could even insert an analog to digital signal converter.

How Do I Choose Which PLC Type I Need?

Now that you understand the basic components of a PLC and the types available, you may wonder how to narrow down your choices. The first thing to consider is whether you’ll be implementing a new system, or adding to an existing one. If it’s a new system your options remain wide open. However, if there’s a system already in place, you’ll need to comply with that system’s requirements.

Now that you understand the basic components of a PLC and the types available, you may wonder how to narrow down your choices. The first thing to consider is whether you’ll be implementing a new system, or adding to an existing one. If it’s a new system your options remain wide open. However, if there’s a system already in place, you’ll need to comply with that system’s requirements.

Below are 6 questions to ask yourself when purchasing a programmable logic controller:

1.Are you implementing this PLC into a new or existing system?

2. What type of environment will the PLC reside in?

3. What type and how many I/O points does your system require?

4. How complex are the processes you’re looking to control?

5. How will your PLC communicate with other networks, systems, or field devices?

6. What programming language will you be using to dictate the PLC’s processes?

PLCs Moving Forward

PLCs are everywhere and they exist in places where we might have never thought, like traffic signals. PLC controllers have been around for more than 50 years and will continue to stay, but, with the rise of “big data”, robotic integration and cloud computing PLCs will have to adapt to these new changes as manufacturing continues to become faster and more efficient.

In the future, PLCs will have to become more robust to withstand extreme climate changes, operate remotely without needing someone to be on-site, and communicate with sensors through the Industrial Internet of Things (IIoT) to collect and analyze data needed to make better choices. PLCs will have to be equipped with higher security as cybersecurity is needed across all industries.

Hopefully, you have a newfound appreciation for the PLC. It’s definitely better than trying to manage hundreds of electromechanical relays. Convinced yet about the value PLCs can bring to your processes? We’re proud to offer you micro PLCs by Lovato Electric in our web store. If you still have questions regarding PLCs, please don’t hesitate to contact us.

|

|