A Guide to Linear Bearings and Rail Guides

Did you know the rolling concept of linear bearings traces all the way back to ancient Egypt? In ancient Egyptian drawings people are depicted moving large stones on a sled with logs underneath; the most basic example of how a bearing works. This is just speculation, though. Concrete evidence of the first bearings dates to 40 BC when a wooden ball bearing was discovered from the remains of the Roman Nemi ships in Lake Nemi, Italy. Since then, bearings have evolved to meet various industry needs. In this blog, we’ll cover a small subsection: linear bearings and rail guides.

Table of Contents:

What is a Bearing?

How Do Bearings Work?

What Are Bearings Used For?

Round vs. Square Rail Bearings

Caged Bearings

Preload Definition

Flange Bearings

View the SlideShare version of this blog

What is a Bearing?

Before we dive in, we’ll define some useful terminology. It’s important to note that many of these terms go by numerous alternate names.

Bearing: A machine element that constrains relative motion to only the desired direction, and reduces friction between moving parts. Therefore, a linear bearing will limit an object’s motion to a linear motion.

Bearing carriage (block): The housing for the bearing balls or rollers which is mounted onto the linear guides (rails).

Guide: This is the mounting system for the linear bearing, also known as rails. Linear bearings can be mounted on either square or round rail guides. For a square (profile) rail, it is important that the guides have perfect parallelism, otherwise it could cause binding or excessive wear.

Race: This refers to the sliding contact points of the balls or rollers in a linear bearing. The point at which the balls/rollers touch the carriage is the outer race. The point at which the balls/rollers touch the rail is the inner race.

Parallelism: When installing a mounting system, the rails must be equidistant from one another at all points. Parallelism is important when mounting a square rail. They need a continuously flat and parallel surface for optimum performance.

Stiffness: This refers to the amount of deformation balls or rollers in a bearing undergo when a load is applied. This is also referred to as deflection.

Preload: Linear bearings need preload to function at their best. Preload eliminates internal clearance between the rail and carriage. Preloading a bearing makes it stiffer and prepares the bearing for the load it will carry.

How Do Bearings Work?

A linear bearing includes a carriage and rolling element. The linear bearing is mounted on either a square or round rail depending on the requirements of the application. The rolling element of the bearing, whether it be ball or roller slides, helps move a load with ease. These are the basics which are adjusted and tweaked to fulfill a wide array of manufacturing and industry needs.

What Are Bearings Used For?

Linear bearings are used in both small and large scale applications. You’ll find them in large industrial automation equipment to move tooling, or in microscopes for precise movements. We’ve even incorporated linear bearings in much of our custom automation equipment.

Linear Bearings in the Medical Industry

Common places you’ll find linear bearings in the medical industry include: surgical and dental tools, diagnostic and laboratory equipment, and pumps. In this field, bearings need to meet certain requirements such as high speeds, low noise, service life and resistance to harsh environments, aggressive chemicals or fluids. They need to be able to handle frequent cleaning as well as provide a smooth, quiet operation.

Common places you’ll find linear bearings in the medical industry include: surgical and dental tools, diagnostic and laboratory equipment, and pumps. In this field, bearings need to meet certain requirements such as high speeds, low noise, service life and resistance to harsh environments, aggressive chemicals or fluids. They need to be able to handle frequent cleaning as well as provide a smooth, quiet operation.

Linear Bearings in the Food & Beverage Industry

Linear bearings in the Food & Beverage industry need to be tough enough to handle harsh environments and constant wash-downs while also conforming to health and sanitation standards. Common bearing applications in this industry include: processing equipment, mixers, blenders, ice machinery, and weighing machinery.

Linear bearings in the Food & Beverage industry need to be tough enough to handle harsh environments and constant wash-downs while also conforming to health and sanitation standards. Common bearing applications in this industry include: processing equipment, mixers, blenders, ice machinery, and weighing machinery.

Linear Bearings in Robotics

Robotics is a fairly new industry, yet linear bearings have proven to be quite useful within robotics. You’ll find linear bearings mostly in cartesian robots (also known as gantry robots) which operate on the X, Y, and Z axes. Important bearing features in this industry include: smooth operation, service life, and load capacity.

Robotics is a fairly new industry, yet linear bearings have proven to be quite useful within robotics. You’ll find linear bearings mostly in cartesian robots (also known as gantry robots) which operate on the X, Y, and Z axes. Important bearing features in this industry include: smooth operation, service life, and load capacity.

Linear bearings are used anywhere there’s a need for linear motion, the tricky part is deciding which type is the best fit. Below, we cover a few different decisions that can arise when shopping for linear bearings and rail guides.

Round vs. Square Rail Bearings

A linear bearing can be mounted on any rail or guide shape which allows the rolling element of the bearing to move freely across the rail. Two of the most used rail types include square (profile) and round rails. To decide which type is best suited for your application, you will need to figure out the unique specifications of your application. This includes: load capacity, stiffness, accuracy, smoothness, size, and overall cost.

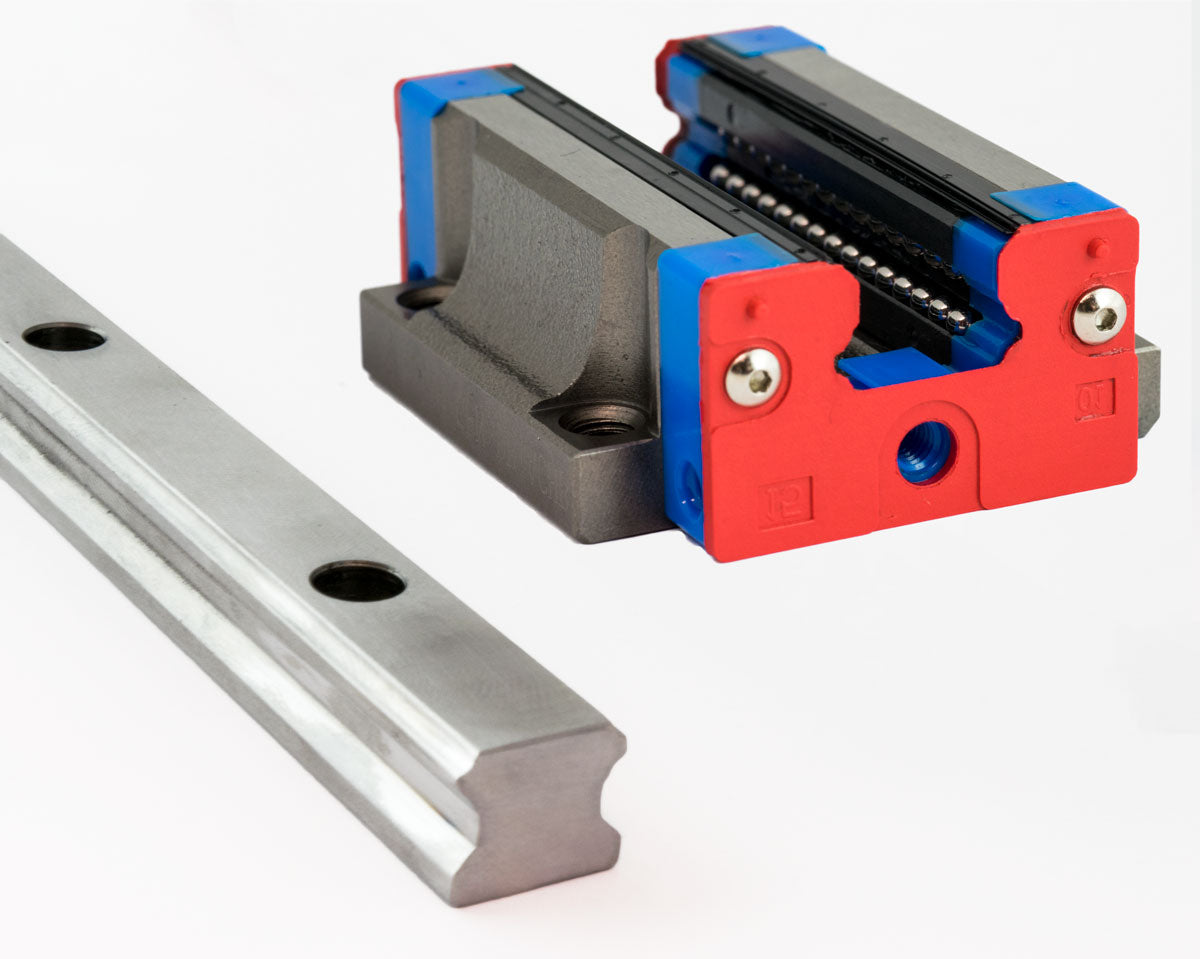

Profile Rail Guide and Carriage Block

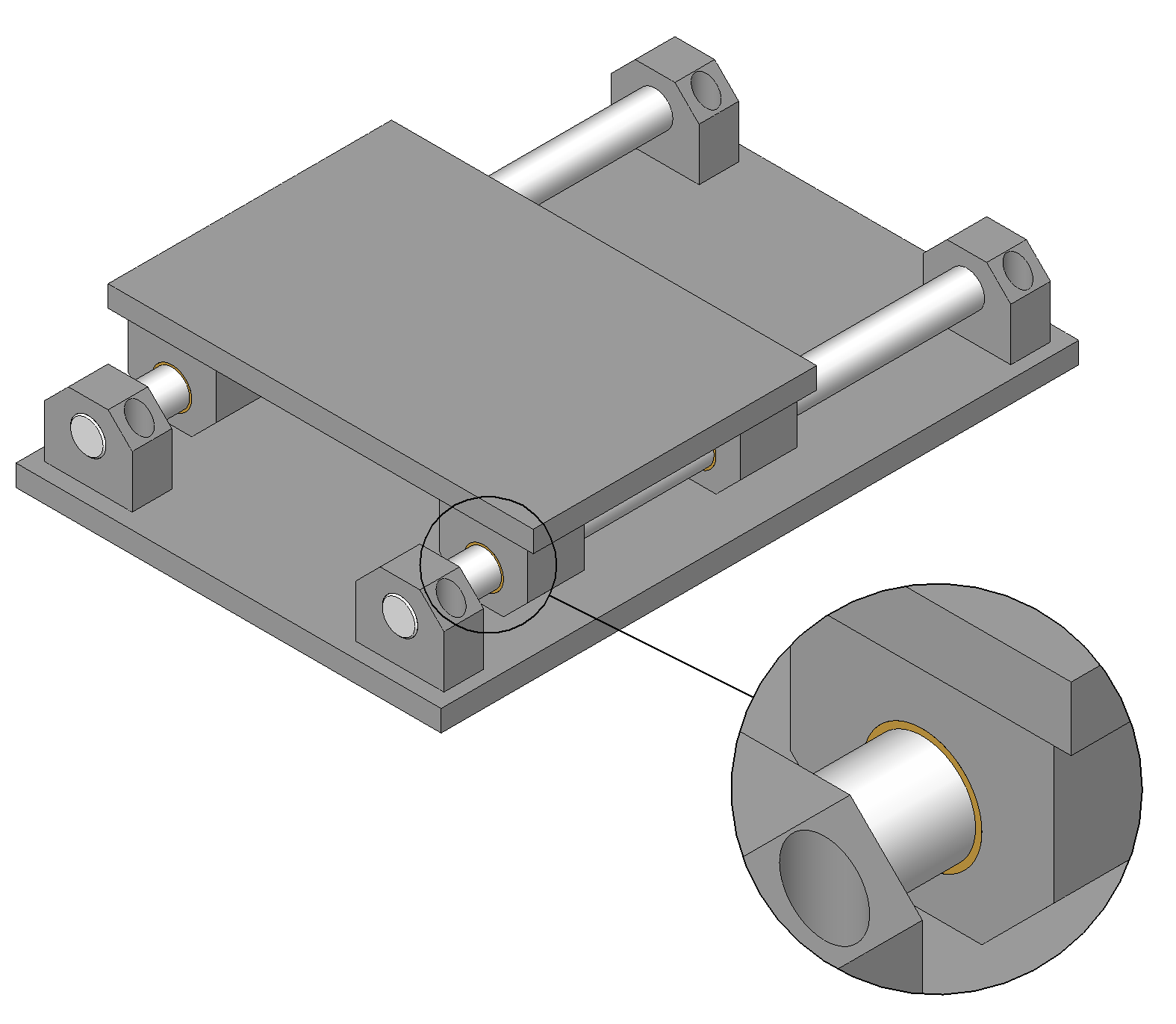

Linear table with Round rails

Square rails used to be more costly than round rails, but nowadays there isn’t much of a difference price-wise. So, choosing between the two really comes down to what is best for you. Square rails and guides offer the benefits of a higher load capacity and precision accuracy. However, to achieve these benefits they require careful installation to ensure parallelism and a flat mounting surface. Round rails, on the other hand, are quicker to install and can handle imperfect parallelism and greater changes in rail height. The downside to round rails is their load capacity isn’t as high as that of square rails.

Caged Bearings

A caged linear bearing includes a retainer for the balls inside the bearing for even spacing. Originally, linear bearings did not include a cage structure and nowadays these are referred to as non-caged linear bearings.

There are several advantages to a caged linear bearing. First, the linear bearing is much quieter due to the metal balls not colliding with one another. This also improves the life of the bearing since there’s less impact on the metal balls. Even spacing between the balls distributes the load equally throughout the bearing. Even spacing also eliminates friction-generated heat allowing for high-speed performance. Lastly, the cage structure is great for storing grease/lubricant and further increases the lifespan of the linear bearing. While it may seem that caged linear bearings are the better option, non-caged bearings are still ideal in low-speed, small load applications. Non-caged bearings are also the economical choice.

Non-caged VS Caged Linear Bearings

Preload Definition

A linear bearing that has been preloaded is like shoes that have been broken in. Those shoes will be much more comfortable and you’ll get much more enjoyment out of them. On the other hand, if you decide to wear new shoes to a party you’ll likely end up with blisters by the end of the night. Linear bearings need preload to function at their best. Loading a linear bearing with larger sized balls, eliminates any internal clearance within the bearing. Afterwards, the bearing will be stiffer and ready to handle the load it will carry. Often times linear bearings are sold already preloaded, so it’s a good idea to check with the manufacturer.

While preload can do good for the linear bearing it can also diminish its life span. That’s why it’s best to choose the amount of preload based on your specific application. Below is a chart with recommended preload amounts based on different applications.

| Preload | No Preload | Light Preload | Medium/Heavy Preload |

| Conditions | Weak impact 2 rails in pair Low accuracy Small resistance Small load |

Cantilever Single rail Light load High accuracy |

Strong impact Strong Vibration Heavy machining |

| Applications | Welding machine Chopping machine Feeding mechanism Tool change mechanism Ordinary XY table Packing machine |

NC lathe EDM Precise XY table Ordinary Z-axis Industrial robot PCB punching machine |

Machine tool NC lathe and milling machine Feeding axis of grinder Tool feeding axis |

*Courtesy of Staf

Flange Bearings

Flange or no flange is entirely optional. A flange mainly helps with mounting things on the bearing, creating a more stable installation. The linear bearings listed in our web store are available with flange or without flange. We also offer various preloads, block sizes, and caged or non-caged ball bearings. To learn more about the brand we carry, visit our Linear Bearings and Rails product page.

Linear bearings come with a multitude of options perfect for detailed customization. Even if you still can’t find what you need, remember we’ve only covered a small sub-set. Our goal with this blog was to clear up any confusion you may have had about linear bearings and rail guides. If you’re still stumped, leave us your questions in the comments below or contact us directly.