Navigating Outsource Manufacturing

As a manufacturer, have you ever pondered the benefits and risks of outsourcing? No matter the size of your operation, small or large, there are always times when outsourcing is an attractive means to an end.

Outsourcing has the potential to save money in many ways. Among the advantages, it alleviates the need for you to acquire additional space and trained labor. As with any cost-saving endeavor, outsource manufacturing has its pros and cons. Understanding your options and preparing a strategy for working with service providers will increase your rate of return and alleviate any loss of profits from mismanaged proprietary knowledge, lost production time, or poor quality.

In the past, many companies were hesitant to outsource any of their manufacturing to an outside source. However, according to Contract Packaging Association's 2018 State of the Industry Report, the contract manufacturing industry has been growing 2 to 4 times faster than the industries it supports.

I. Outsource Manufacturing and Its Subsets

II. Why Outsource?

III. What are Manufacturers Outsourcing?

IV. Recognizing the Pitfalls of Outsource Manufacturing

V. Choosing an Outsource Manufacturing Partner

Outsource Manufacturing and Its Subsets

In outsource manufacturing, a manufacturer decides that a specific task or tasks would be better performed by an outside specialist versus completing the job in-house. The manufacturer will then hire or partner with a suitable outside contractor. Outsourcing is utilized by both large and small manufacturers to complete work, which may include assemblies, sub-assemblies, custom parts, etc.

The following industries are all outsourcing jobs:

- Aerospace, aviation, and defense

- Automotive, truck, and heavy equipment

- Biotechnology and pharmaceutical

- Food processing and manufacturing

- Textile

- Plastics and chemicals

- Furniture

- Information and communications technology

- Paper and paper products

To narrow down your search for a suitable partner, you first need to understand the different subsets of outsource manufacturing. The subsets of outsource manufacturing are primarily defined by production type, amount, and workflow.

For starters, you will either allow your contractor to source materials or you will provide the materials for builds.

Toll Manufacturing (Toll Processing)

Contract Manufacturing

Project Shop

Job Shop

Batch Flow Shop

Assembly Line

Continuous Flow

Why Outsource?

Your business is successful. Your operation is designed to incorporate what you do best, but what about those pesky manufacturing outliers? Outsourcing is for the outlying prototypes, assemblies, or components that are not part of your core competency. To be an expert in all areas takes added investment. If you are not interested in vertical integration or starting a new department, then finding an experienced service provider for outsourcing allows your business to avoid costly investments and concentrate on what it does best.

Benefits of manufacturing outsourcing:

-

Avoids added expenses including those arising from additional workers, working space, supply chain management, and equipment acquisitions

-

Ensures expert input and quality control in designs, components, and eventually builds

-

Flexible services that allow for product re-configurations or prototypes

While cost savings are number one, the benefits of outsourcing are far-ranging and dependent on the industry and services desired. A contract manufacturer will know the ins and outs of the industry, which will garner you quality materials and labor at the best prices.

What are Manufacturers Outsourcing?

Manufacturers outsource jobs that rely heavily on specialized trade skills and equipment. Automation technology is becoming less mechanical and more electronic and electromechanical. Today’s technological advances are increasing the demand for service providers that can provide a competitive advantage with state-of-the-art equipment and tech-savvy personnel. This tectonic shift is creating a huge obstacle for manufacturers. Consumers are basing purchase decisions on the perceived benefits of technological improvements in combination with the price point. What used to be less complicated to build has suddenly become futuristic. In this environment, the profit gain or loss from your outsourced components will depend more on your relationship with and the talents of your service providers.

Electromechanical Manufacturing

Industrial Control Panels

Control panel enclosures, or electrical enclosures, are specially designed cabinets that hold industrial components. Their purpose is two-fold: to protect workers from electric shock and and to protect the components inside from their environment.

Read more about electrical enclosures in our TecTalk blog: “Electrical Enclosures Simplified | NEMA Ratings, Material, & Accessories”

Printed Circuit Boards (PCBs)

Overmolding

Overmolding is the process of surrounding a component with plastic. A plastic resin is injected around electrical connections, thus improving the longevity and reliability of the assembly.

Read more about low-pressure overmolding on our TecTalk blog, “Overmolding for Electrical Assemblies.”

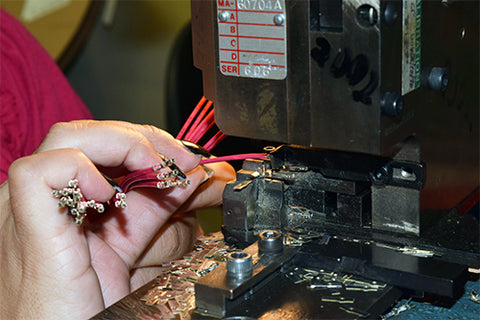

Custom Cable and Wire Harness Assembly

Custom cables and wire harnesses are assembled for specific applications based on a customer's technical requirements. Typically, the customer will provide the contract manufacturer with technical drawings.

Read about a wide range of cable and harness topics on our TecTalk blog:

Industrial Automation

Read more about automation on our TecTalk blog “Understanding Industrial Automation in Industry 4.0.”

Custom Automation Machine Builds

New equipment builds will fall under one of three design categories: fixed or hard automation, programmable automation, and flexible or soft automation. Your machine design will be determined based on your products' production requirements.

Industrial Control Systems

Industrial control systems are a key component of any automation system. PLCs (Programmable Logic Controllers) and HMIs (Human Machine Interfaces) can also be added to existing machines, replacing the need to purchase brand new equipment.

Read more about industrial control on our TecTalk blogs, “PLC’s Explained: Programmable Logic Controller Basics” and “Understanding HMIs.”

Machining and Fabrication

Machined Parts

Machine shops typically use a combination of conventional and CNC milling, routing and turning equipment. Your parts can be manufactured based off of technical drawings and hand sketches, or even reverse engineered.

Read more about machining processes on our TecTalk blog, “Machining Processes: Turning, Milling, and Drilling—Trimantec.”

3D Printing

Conversely to milling and turning, 3D printers create parts via additive manufacturing. If you're looking for a short production run or need a complex shape, then 3D printing will be the most effective manufacturing method.

Read more about 3D Printing on our TecTalk blog, “The Future of 3D Printing.”

Sheet Metal Fabrication

Sheet metal fabrication is the process of cutting, bending or assembling metal structures. Sheet metal is known for its durability, so these fabrications are ideal for end-use applications.

Welding

Welding services typically go hand in hand with sheet metal fabrication. Most fabrication shops can create simple assemblies like handrails and brackets, as well as complex machine frames and industrial weldments.

Read more about welding on our TecTalk blog, “Tig Vs Mig Welding | What’s the Difference?”

Recognizing the Pitfalls of Outsourcing

With today’s abundance of reliable outsource manufacturing providers, why would you not take advantage? There are always risks involved in relying on others to meet your deadlines and expectations, but if you are prepared, you can minimize potential production disasters.

Here are some steps to minimize risks:

- Choose your outsource partner wisely, so you can avoid the need for micromanagement or having to switch partners mid-game.

- If your outsourced design is proprietary and of huge value as a competitive advantage, you will need a contractual agreement. A detailed contract and non-disclosure agreement can help protect what is yours. Otherwise, you will need to consider internal sourcing solutions.

- Involve internal players in outsource decisions pertaining to their area(s) of expertise to avoid conflicts down the road.

- Strive for a complete, accurate, and on-time request for proposal.

Choosing a Manufacturing Partner

When looking for a partner there are many characteristics to consider beyond price. You may obtain a low price upfront but find yourself nickel and dimed later by troublesome issues.

To prepare for interviews, make sure to ask the right questions.

Skilled Labor

-

Pick a partner that can provide the following:

- A highly skilled and diverse workforce that will be dependable.

- An established reputation - don’t leave your production to a novice.

- A facility tour and ask to see work comparable to the job you will be submitting.

Capacity

- Meet with the project manager/scheduler to determine rapport.

- Ask how rush jobs are handled and overtime fees apportioned.

- Discuss 'what-if' scenarios, such as machine breakdowns and their impact on production.

Location

- Benefits of choosing domestic, even if the cost is higher:

- A domestic provider will have expert advice and provide guidance on industry standards.

- With your contract provider nearby, you have access to information on your order almost immediately.

- A local, small-batch producer can help you work the bugs out of any new product design issues.

Conclusion

Understanding your options before talking with contractors will give you more control in the outcome of your partnership and products. There is more than just price to consider when choosing your partner. The best partner will be process certified, have a great reputation, and provide you a product within spec in the shortest amount of time. For original equipment manufacturers (OEM) the question is not should I outsource, but which type of outsource manufacturing will garner me the best overall return on investment (ROI)?